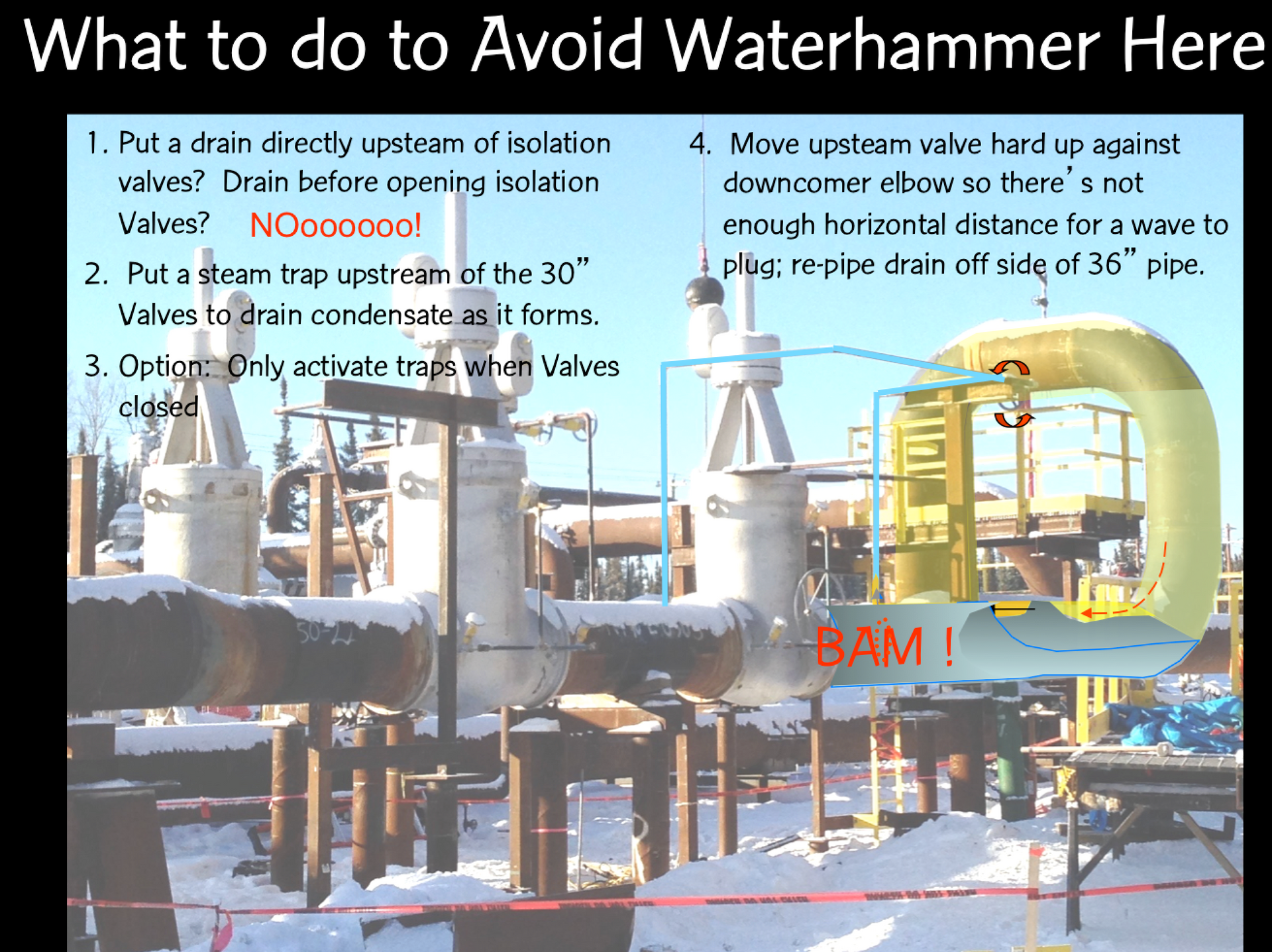

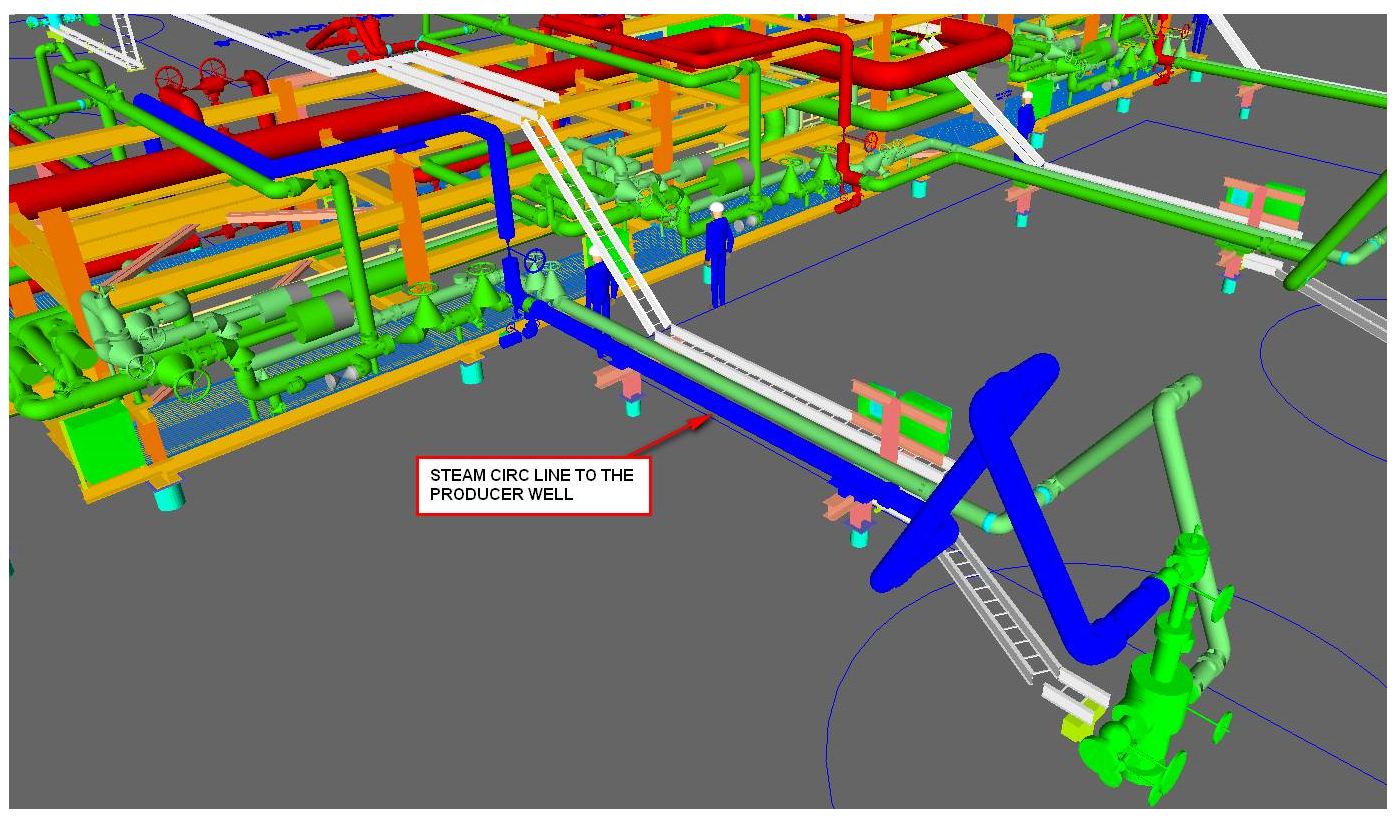

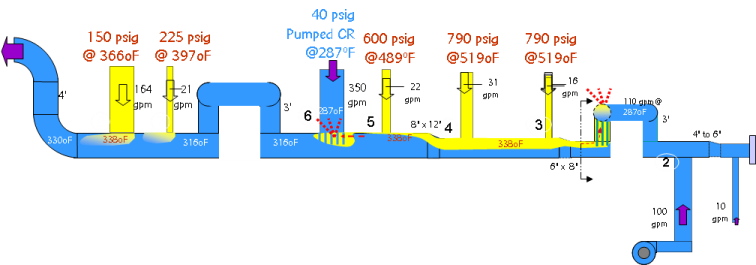

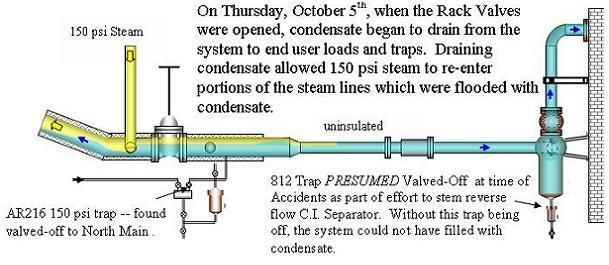

For ConocoPhillips, Surmont 2 in the Wood Buffalo Region of Alberta, CA, beginning in Feb 2014 thru 2016 worked with Commissioning and Start-up Team to engineer the potential for waterhammer out of their many kilometers long steam distribution system. The effort resulted in re-engineering several sites where water hammer could occur. An example is shown in the slide at right made to explain the problem at TJ's Corner where the north side of the steam distribution system could be isolated from the south side. Should the steam Valves ever be closed to the north section of the site (while the south side stayed active), condensate could build up upstream of the isolation valves as depicted so that when the valves were reopened, condensation induced waterhammer could occur in the horizontal portion of the line. The section of line along with two others identified were re-engineered prior to start-up of the system.

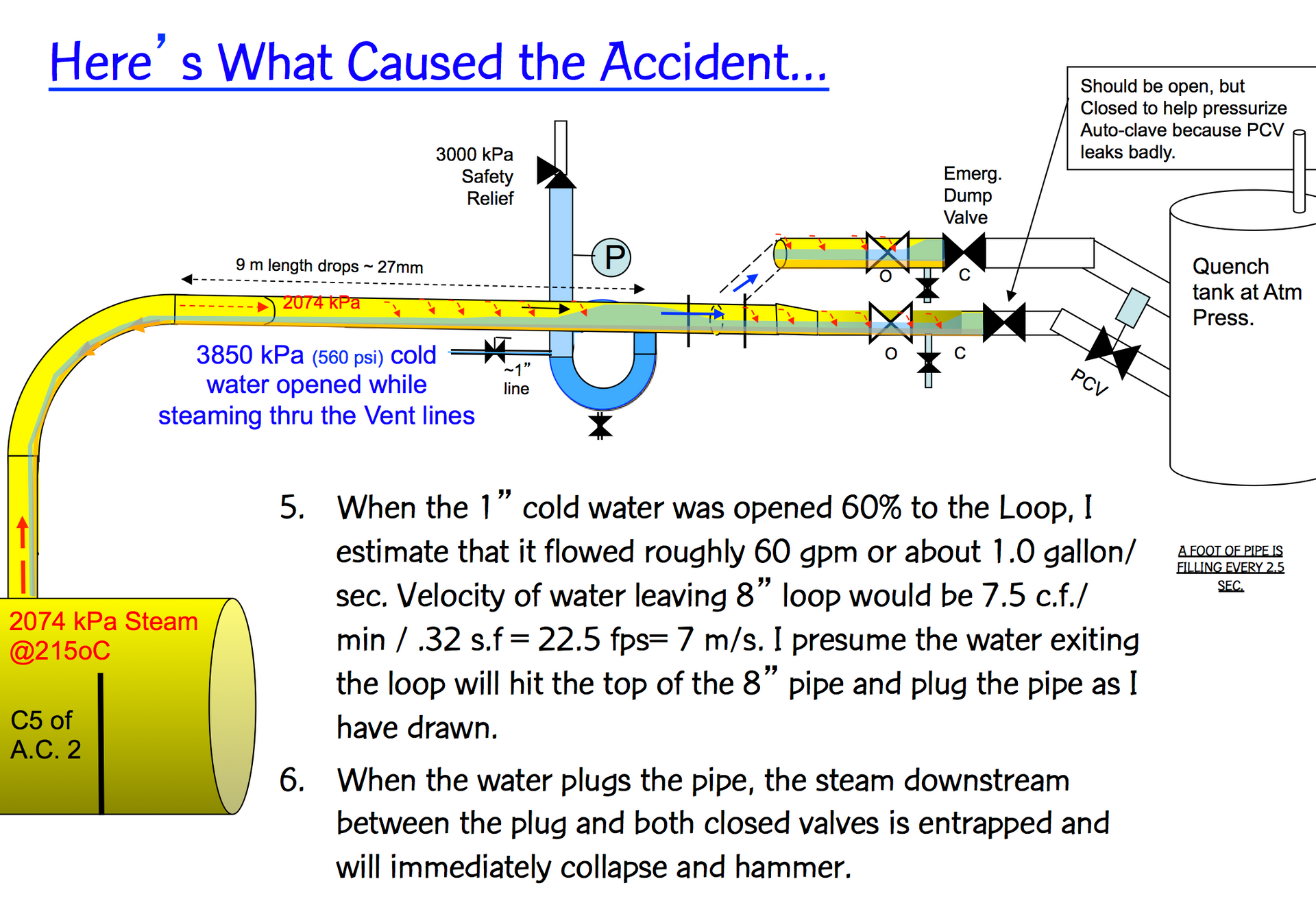

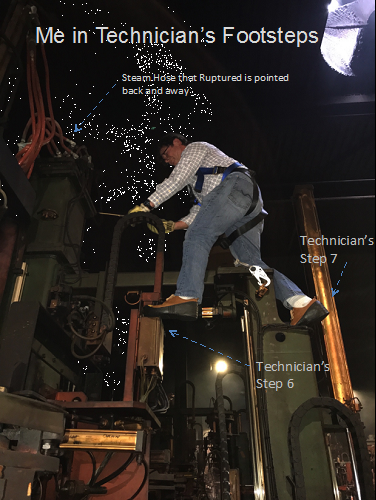

In July of 2015 spent 7 days on site during start-up of the Surmount 2 steam system troubleshooting waterhammer concerns primarily in OTSG Blowdown piping, The system at Surmont was unique because rather than blowdown dumping to a pond at atmospheric pressure, the blowdown was piped to pressurized tanks. Troubleshot the reasons why waterhammer was occurring during start-up of the new Plant and suggested alternative designs, instrumentation, and operating procedures to prevent waterhammer. Months later in July 2016, was asked to review and comment on Risk Evaluation Report which I found to have incorrectly estimated the possible waterhammer forces that the blowdown piping might experience. After submitting my report 27 July 2016, was ask to provide waterhammer worst-case overpressure values and pulse duration times to the Risk Evaluation Firm. Completed 24 August 2016 but more detail was requested by ConocoPhillips Engineers. On 18 Sep 2016, submitted Power point presentation of scenarios w/ descriptions chosen (by me) for which the worst case waterhammer intensities were calculated and assumptions and calculations included. Conoco- Phillips responded with a request to examine and calculate waterhammer overpressure and pulse duration for waterhammer scenarios that they had selected for evaluation and input to the risk analysis performed by others.