Toilet Waterhammer

Pipe Rattling From Waterhammer

A pressure gauge reacting to the waterhammer emanating from the toilet tank when the fill valve shut off. The gauge is connected to an outdoor hose bibb located 16 feet downstream of the cold water takeoff to the toilet. The red needle shows the highest pressure recorded by the gauge. After the waterhammer, it's pegged against the zero post of the 200 psi gauge.

Sound Volume in My Sister's Bedroom

This page shows waterhammer being initiated in the toilet tank at my parents' home in St. Louis and explains what I did to troubleshoot the problem. I did this work as a tongue-in-cheek example for an ASHRAE speech to Atlanta HVAC engineers to demonstrate the principles of waterhammer. The short video clips above illustrate just how forceful the water hammer was in the house.

The first requirement for waterhammer to occur is to have a fast-acting shut-off valve. Pictured in the video at the top of the page is the relatively new toilet fill valve assembly which replaced the old ball cock design when it wore out. Apparently the new type flow valve (manufactured by Fluidmaster) shuts off flow more abruptly than the old ball cock assembly. From slow motion viewing of the video, I estimate that the last phase of complete shutoff takes about one frame of film, i.e., about 1/30 sec.

Why the new fill valve shuts off more quickly is, I believe, a function of the manufacturer's design AND the pressure in the house. The gauge below placed on a hose bibb outside the house shows the water pressure was over 90 psi. 65 psi is about normal for a home. (The gauge reads high after being whacked by waterhammer several times).

The house, built in 1970, had no Pressure Reducing Valve (PRV) to reduce incoming county water pressure.

High water pressure can, in general, make a home more susceptible to noticeable water hammer because it causes water to flow at high velocity throughout the water delivery system. The force of a Waterhammer is directly proportional to the water velocity at the valve where the water is stopped. Higher water pressure begets higher flow velocity which begets more severe waterhammer. That said, while high water velocity causes more severe waterhammer, it doesn't determine if waterhammer will happen.

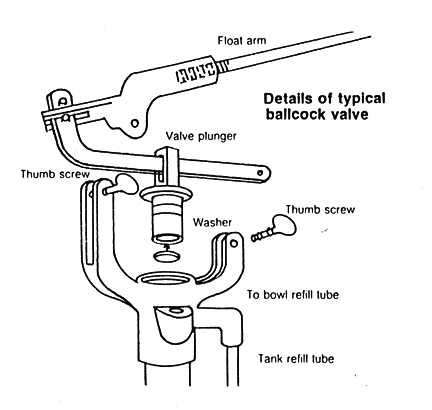

In the case of the new toilet fill valve, I suspect the high pressure causes a problem which actually enables the waterhammer. The old ball cock design, shown disassembled below, closes by using the force of the levered float to force the valve to seat against system water pressure in the house. This is how HVAC control valves work, with which I'm more familiar, they close against the water pressure. Experience has shown that if an HVAC control valve is installed backward so that the valve's actuator tries to close the valve with the aid of system water pressure, when the valve nears closure, the pressure across the valve can slam the valve shut.

Diagram from http://www.toiletology.com

The new Fluidmaster design, unlike the ball cock design, uses the system water pressure to close the valve. As the float lifts, a small arm connected to the float opens a passage that allows system water pressure to fill a diagram which closes the valve. High pressure in the system can, I suspect, cause the diaphragm to fill too quickly and slam the valve shut. Thus, the second requirement for waterhammer is high pressure. A diagram of the Fluidmaster fill valve works is shown at: http://support.fluidmaster.com/

Note: The manufacturer has disabled the link above. Another excellent and very long and detailed reference for toilet nerds on how a modern Toilet Fill Valve works is:

How A Toilet Silent Fill Valve Works - Helpful Colin

A third requirement for waterhammer to occur is that there be a long run of pipe from the fixture that is initiating the waterhammer back to the water heater or a larger pipe. In my parent's case, there was 39 feet of 1/2" copper tube from the toilet back to a 3/4" main and another 6 feet to the tee into the water heater. At a pipe expansion or the water heater there will be a reflection of the waterhammer compression wave which will partially cancel the waterhammer pressure if it has time to race back to the closing valve before the valve fully closes. In other words, there's a race between the valve closing and the reflected wave making its way back from the reflection point. This is why, for waterhammer, it's not only important that the valve close quickly, but the pipe run between the water tank or larger pipe main to the initiating device (the toilet) be far.

A fourth requirement is that there be no waterhammer arrestors. The house, as was typical, almost certainly had waterhammer arrestors built into the plumbing distribution system. Before plumbing codes changed for modern homes, the arrestors would have consisted of stubb-ups of copper tubing which were supposed to trap air when the plumbing system was first filled with water. A pressure shock caused by a quick closing valve would be absorbed by the trapped air in the pipe which acted as an inexpensive shock absorber.

The fallacy of this scheme is that water over time, if at higher pressure than that from which the municipal water supply is drawn, will absorb air and thereby eventually "waterlog" the arrestors. Water pumped up to municipal water pressures for delivery will generally always be above the pressure at which the water is drawn. Thus, the old-style water hammer arrestors eventually waterlog unless periodically recharged with air by draining down the system and letting air refill it. I presume that's why this type of waterhammer arrestor is no longer used.

Modern water hammer arrestors consist of an air pocket separated from the water by a piston or diaphragm so the air cannot be absorbed. I identified and purchased from Sioux Chief a waterhammer arrestor designed specifically for toilet service. It's shown installed in the photo below directly under the toilet tank. It did not work. The manufacturer (I talked to their Engineer) sent me a replacement, but it didn't improve the situation either. I can only conclude that the design is faulty although I believe the concept is sound.

Experiments

As an experiment, I conjured up a simple waterhammer arrestor by attaching a capped hose to the sink faucet next to the toilet and opened the faucet to connect the hose into the plumbing system. In the video above, you'll note–no water hammer when the toilet fills valve closes. The waterhammer pulse is negatively reflected from the hose. The capped hose also worked by connecting it to the outside hose bibb downstream of the toilet take-off and opening the faucet there to pressurize the air-filled hose.

As an experiment, I conjured up a simple waterhammer arrestor by attaching a capped hose to the sink faucet next to the toilet and opened the faucet to connect the hose into the plumbing system. In the video above, you'll note–no water hammer when the toilet fill valve closes. The waterhammer pulse is negatively reflected from the hose. The capped hose also worked by connecting it to the outside hose bibb downstream of the toilet take-off and opening the faucet there to pressurize the air-filled hose.

What Could be Done to Stop the Waterhammer

1. Provide PRV on incoming water line to limit pressure. This solution has a downside. It will increase time to fill the toilet tanks after flushing and reduce flow at showers, to name two disadvanges, in the same proportion as water hammer over-pressure is reduced. A PRV cost about $35.

2. Provide pipe supports if pipe is loose. This reduced the "twanging" considerably at my parents' house although the "thunk" of the initial waterhammer remained. It will not reduce the over-pressure generated by the waterhammer. The supports are cheap and are merely hammered into wooden floor joists.

3. If your house is old, you could reactivate the original water hammer arrestors by refilling them with air. I.E., after shutting off the water supply, drain the plumbing system of all water at a low drain (often the water heater drain) and open high faucets to let air fill the system. This recharges the old stubb-ups with air, so they once again resist waterhammer once the system is refilled.

There is a possible problem with this solution. Bacteria may be able to grow in the dead-ended air spaces of the old type water hammer arrestors. Legionella has been shown to thrive between water temperatures of 77°F and 115°F*. While I haven't heard of Legionella being specifically reported in old air pocket type arrestors, I doubt if anyone has looked. Legionella has been found in an alarmingly high proportion of hospital domestic water systems which have been tested for it. For this reason, I would recommend the new piston type arrestors (even though the type I tried didn't work) be installed in which air and water are not in contact rather than recharging the original arrestors with air.

4. Replace the fast-acting toilet fill valve with one that will not close quickly–like the old ball cock on an arm. (I don't have a product recommendation).

About Me: Most importantly–I'm not a plumbing engineer. I investigate waterhammer accidents in steam systems as is evident from the rest of this web site. I researched the problem discussed on this page for a speech to demonstrate the principles of waterhammer to the Atlanta ASHRAE Chapter, and afterward, as a hobby. Where i say above "I suspect" or "I believe", I've tried to give my reasoning so a knowlegeable reader can see where I'm coming from.

*Preventing Legionallosis, William F. McCoy, PhD, June 2006 ASHRAE Journal.

Waterhammer Seminars

All Rights Reserved | Kirsner Consulting Engineering