Steam Training for Operators and Engineers

It is better to teach a man to fish... than to hit him with a fish... (usually).

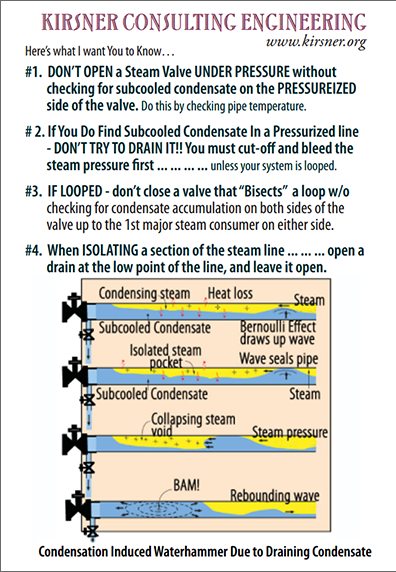

Condensation-Induced Water hammer occurs as incoming steam intrudes into the blue-colored condensate from the left as the condensate slowly drains through a cracked-open valve at the right. CLICK for another water hammer video. ( Turn up the Volume to hear the water hammer snap).

Steam wafts out of a fractured 6" Class 250 cast iron valve after killing a worker.

Understanding Water Hammer in Steam Systems

What steam workers need to know before operating a steam valve in a high-pressure

steam system and what Engineers need to know before they design one!

Over 3000 hours have gone into developing the most comprehensive seminar available anywhere on how to operate and maintain high-pressure steam systems so as to avoid life-threatening steam accidents. It's based on research done since 1973 as well as a comprehensive library of scientific papers published since then. The Seminar includes videos of water hammer in the lab, live demonstrations of a rapid steam bubble collapse, and over 200 animated slides that depict step-by-step what's going on inside steam lines. (Link to the Program below). The first 4 hours gives steam workers a gut understanding of what really causes water hammer in steam pipes.

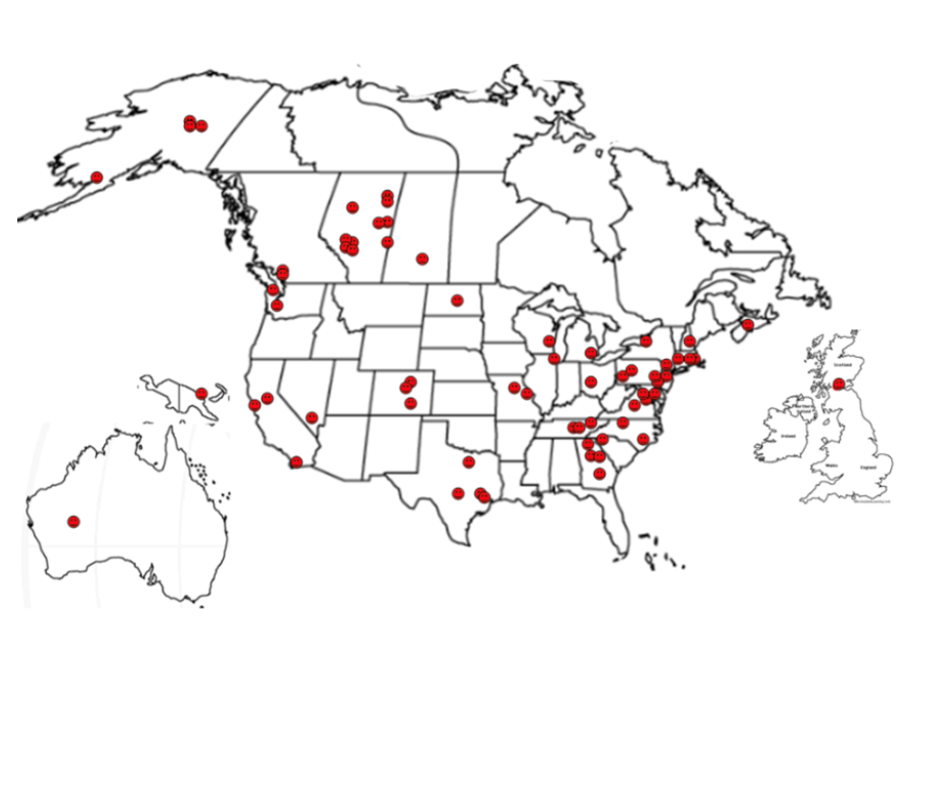

The second 4-1/2 hours covers topics critical to specific steam layouts like: Accidents in "looped" distribution networks, the danger of flooded manholes and submerged steam lines, and start-up accidents where unforeseen conditions have killed workers. Examples are drawn from actual accidents which, in most cases, were investigated by the presenter himself (see Accident Investigations). While this intensive 2-day, 8 hour seminar was designed specifically for steam fitters and operators to keep them from repeating the mistakes made in previous accidents, Engineers get the most out of the seminars. (See Feedback below). This seminar has been refined over 150 presentations primarily in North America to over 4000 attendees. An abreviated one-day 6.5-hour seminar is offered for shift workers that can't be assembled for 2 days. Special Topics for SAGD are linked below.

First Seminar, August 1998 at Fort Wainwright, Alaska.

Upcoming Seminars:

- Suncor Energy Company: Two 8-hour seminars for Engineers the week of March 11 2024 at Calgary and Firebag SAGD Site.

Seminar Recipients:

Seminar Recipients are listed below by Category and shown by location at right, or, link to a larger World Map. Where "See Evaluations" appears below, attendee evaluations are linked to the seminar, or, you may request evaluations from any seminar. Where I have done repeat seminars for clients, the most recent is listed first.

Click to expand each seminar category below:

-

Engineering & Oil Sands Design Groups ‒ 14 seminars

- Suncor Energy: two 8-hr Seminars for Engineers/ senior operators: Calgary 11,12 March 2024, and Firebag 13,14 March 2024. Link to Evaluations of Seminar.

- WorleyParsons Process Engineering Department, Calgary, 15,16 Oct. 2012

- AMEC Power Engineers (see above under Kearl Joint Seminar)

- Vista Projects, Design Engineers, Calgary, AB, 2 seminars 2,3 Nov. 2011

- IMV Projects, Design Engineers, Calgary, 20 Apr. 2007. See Evaluations (and previously 4 seminars 25-28 Oct. 2011)

- WorleyParsons & Suncor Engineers, Calgary, AB, 27 Aug. 2009

- Calgary Open Seminar for Engineers, 24 Nov. 2006

- Rohm & Haas, Houston, TX, 28 Feb. 2006

-

Universities -32 seminars

- Eindhoven University, Netherlands- (April 11th 2023) 4 hour Seminar to paid attendees for 14 International Conference on Pressure Surges

- Harvard University, Cambridge, MA—Two 8-hr Seminars on 14,15 & 29,30 Nov 2022, and before this, a 2-day 12-hour Seminar on Sep 17,18, 2018, and previously Sep 2015, Jan. 2013. Mar. 2010, Jan 2009, See Evaluations, Jan. 2013, and Sep 2015)

- University of Massachusetts, Amhurst, MA, March 23,24, 2017

- University of Missouri, Columbia, MO, 2 seminars, 16,17 Jun. 2016 (and previously in Oct. 2001, and Apr. 2003)

- Vanderbilt University, Nashville, TN, Oct. 2015

- Massachusetts Institute of Technology, Cambridge, MA, 27,28 Dec. 2013 (and previously 1,2 Dec. 2008)

- University of Alaska, Fairbanks, AL, 1,2 Oct. 2013 (and previously in Jan. 2007)

- Duke University, Durham, NC, 5,6 Aug. 2013 (and previously 21,22 Apr. 2009)

- University of Virginia, Charlottesville, VA, 8,9 Jun. 2011

- University of Chicago, Chicago, IL, 19,20 Apr. 2011 See Evaluations

- Princeton University, Princeton, NJ, 27,28 Jan. 2011 (and previously in Sep. 2010)

- St. Francis Xavier University, Antigonish, Nova Scotia, Canada, 15,16 Dec. 2010

- University of Maryland and Suez Energy, College Park, MD, 27,28 Jan. 2009

- University of Regina, Regina, Saskatchewan, Canada, Sep. 30, Oct. 1, 2008

- University of Michigan, Ann Arbor, MI, 12,13,14,15 Aug. 2008

- University of British Columbia, Vancouver, Canada, Apr. 2001, part II in Jun. 2002

- US Military Academy, West Point, NY, Sep. 11, 2000

- University of North Carolina, Chapel Hill, NC, steam operators and engineers, Dec. 3, 1999

-

Oil, Oil Sands, SAGD Companies, and Mining (Also see Oil Sands Engineering Firms below) ‒ 61 seminars

- Newcrest Mining Papua New Guinea, Lihir Island, 2 Seminars April 13 thru 20, 2017 See Evaluations

- Tesoro Refinery, Mandan, North Dakota, 11,13 Sep. 2017 (and previously 6,7 June 2016)

- ConocoPhillips, Surmont 2, North of Ft. Mac, 25,26,27 Aug. 2014 (and previously 4,5,6 Feb. 2014)

- MEG Energy, Alberta Dec 9-13, 2013

- Cenovus Cristina Lake 13 Nov. 2013 on site (previously 1,2 Oct. 2012 in Calgary and 1,2, Oct. 2014 in Bonneyville)

- ConocoPhillips, Surmont 1 outside Fort MacMurray, 7 Oct. 2013

- Imperial Oil, Cold Lake, Alberta Apr. 30 thru May 2, 2013 See Evaluations

- Conoco Phillips, Calgary, 22,23 Apr. 2013

- Canadian Natural Resources, Cold Lake, AB, 25-29 Mar. 2013

- Pengrowth Engineering, Calgary 8-12 Sep. 2014 (and previously 29 Nov. 2012 and at their Cold Lake Site)

- Cenovus Energy, Cold Lake, Alberta, 29 Oct.-1 Nov 2012

- Dover Operating Company Calgary 19 Sep. 2012

- Kearl Oil Sands Operators at Kearl Lake Camp north of Ft. MacMurray, June 11 & 13th

- Kearl Oil Sands Engineers & Supervisors, Calgary, Feb. 2011 (and previously Jan. 2009, Feb. 2009,Jun. 2010, Nov.)

- Cenovus Energy, Calgary & Cold Lake, Alberta, 1 seminar for Engineers, 3 for Operators 9-13 Apr. 2012

- Minara Mining, Murin Murin Australia Site to engineers and supervisors, 28 Jun. 2010

- Imperial Oil, Cold Lake, Alberta, 1 Apr. 2010 See Evaluations (previously Nov. 2006, 25,26,27 Sep. 2007, 30,31 Mar. 2010)

- Suncor Energy Firebag SAGD Site, McKay River, Alberta, 2 Feb. 2010

- Suncor Oil Sands, Ft. McMurray, Alberta, 19 seminars Feb.-Mar. 2007,

- Husky Energy, Lloydminster, Alberta, 23,28, Nov. 2006

- Air Liquide, Houston Texas, 3 Mar. 2006, 24 Feb. 2005

- BP Refinery and Chemical Complex, Scotland, UK--Feb 2001

-

Utilities and District Steam Systems ‒ 17 seminars

- Capital Steam Plant, Washington, DC, 27,28 Oct. 2019 (and previously 25,26 July 2012, 22 July 5 and 5 Aug. 2008)

- XCEL Energy Rocky Mountain Power Plant, Keenesburg, CO, 21,22 Jul. 2014

- XCEL Energy, Denver Cherokee Plant and Pueblo Comanche Plant 24,25 Jun. 2013 (and previously Arapahoe 150 MW Plant, Denver; 850 MW Comanche III Plant, 13,14,15 Jun. 2011)

- Veolia Energy and U. of Pennslvania Steam Fitters & Operators in Philadelphia, PA, Jun. 19-22

- XCEL Energy, Denver, 2 seminars 13,14 Jul. 2010 (and previously in Apr. 2007 for Joint Seminar for Supervisors and Managers at annual educational meeting)

- NRG Energy, San Francisco 7,8 Apr. 2009.

- NRG Steam Plants, Pittsburgh, PA, 19 Aug. 2008

- Trigen Energy Corporation hosted by Boston Trigen 26,25 Nov. 2007

- Trigen Energy Corporation, Philadelphia, PA, 11 Feb. 2000

-

Military, NASA, Brookhaven National Laboratory ‒ 17 seminars

- Norfolk Naval Base, 27,28 June 2022

- Naval Submarine Base, New London, CT, 24-27 March 2015 (and previously 6,7,8 Aug. 2008)

- Norfolk Naval Station, 2 seminars, 20,21,22,23 Sep. 2011

- Brookhaven National Lab, NY, 2 seminars: 5,6,7,8 Apr. 2011. (Previously 2 seminars Feb. 2006)

- NASA Langley Research Center, 25,26 Mar. 2008

- Ft. Wainwright Corps of Engineers, Fairbanks, AK, Jan. 30 thru Feb. 2, 2007

- Puget Sound Naval Shipyard, Bremerton, WA -- August 2006

- Newport Naval Station, 16,17 Aug. 2005 See Evaluations

- San Diego Naval Station, 11 May 2004 & repeated 14,15 Jul. 2004

- Fort Wainwright Steam Fitting Crew, Fairbanks, Alaska--August 1998

-

Industry, Technical Associations ‒ 18 seminars

- American Plant Maintenance (APM), Woburn, MA, 4 hr Seminar 15 August 2023

- Samsung Semiconductor, Austin Tx- Two 8 hr Seminars AUGUST 2023.

- Lockheed Martin, Oswego, NY, 2 seminars 24,25 Oct. 2017 (and previously 5,6 Dec. 2006 (Operators/Supervisors)) See Evaluations

- Thermacor, Dallas Fort Worth Area, 28 Mar. 2012

- Elliott Group Turbines and Compressors, Jeannette, PA, 17,18 May 2011

- Center for Disease Control (CDC), Atlanta, GA, Apr. 2010

- International District Energy Association, Boston Feb. 2008 with Part II in Durham, NC, Feb. 2009

- State of Wisconsin Annual Heating Plant Conference, (Mini-Seminar), Madison, WI, 11 Sep. 2008

- Fort McMurray Open Seminar, Keyano College, Alberta, 30 Nov. 2006

- Huron (formerly IBM) Campus, Endicott, NY, 26,27 Sep. 2006

- Washington State Governmental Facilities, Olympia, WA, 29,30 Jun. 2004

- Freescale (formerly Motorola) Semiconductor Plant, Austin, TX, 1,2 Jun. 2004

- Kaba-ILCO Manufacturing, Winston Salem, NC, 14 Feb. 2002

-

Nuclear ‒ 2 seminars

- Oconee Nuclear Power Plant, 15,16 Dec 2015 (and previously Sept 2003)

The Seminar Program

Understanding Waterhammer in Steam Systems

Part I- Obtaining a Gut-Understanding of Condensation Induced Waterhammer - 4-1/2 hours)

1. Quiz--Let's Review what you already "know" about waterhammer in steam systems.

2. Condensation-Induced Waterhammer-- This is the kind of waterhammer that kills operators!

- The worker who opened this steam valve was killed. What would you have done to open this valve?

- What Everyone "thinks they know" about Waterhammer.

- What Manufacturer's literature and Most Authorities say causes Waterhammer.

- Acquiring the Correct Mental Model--Let's look inside a steam pipe to see what's going on.

- How Condensation-Induced Waterhammer Actually Occurs in Steam Systems. Live demonstration of rapid steam bubble collapse in a 5L beer mini-keg.

- Video of water cannon experiment showing water moving fast into a steam bubble collapsing.

- Waterhammer, the Phenomena-- What makes it so forceful? Live Demonstration. There's an engineers' and non-engineers version of this discussion.

- Video of Steam Waterhammer in a Glass Model as it occurs in a horizontal steam line. This video is run in slow motion so as to show all the detail of what's happening.

3. Return to the Initial Accident. This is what happened when the worker opened the steam valve.

1. Would a bypass on the valve have mattered?, How about a drain?, What about re-activating the trap?

2. Is there any way to have activated the system while avoiding a waterhammer?

4. What Won't Hammer and What Will. A discussion of the circumstances that must align for a Condensation-Induced Waterhammer to occur.

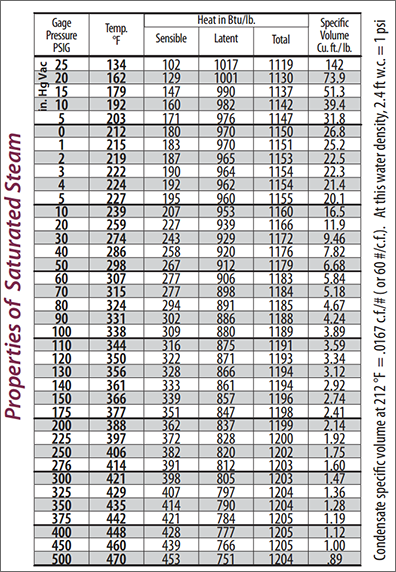

5. Using Infrared Guns Correctly and Alternatives i.e., How to find subcooled condensate in steam systems

- Infrared Guns --You've got to know the "emissivity" of the object and the "field of vision" of the Gun to get a reliable measurement:

- Infrared Camera Photos showing error due to emissivity

- "Field of View" explanation

6. Recognizing an Unsafe Trap Assembly Design (yes, engineers make mistakes)

7. Now, Do You Know Enough to avoid a steam waterhammer accident? Re-visit the Fatal Accident with which we began and list what should be done before opening any valve in a high pressure steam system.

Part II- Lessons from Real Accidents & Advanced Topics

8. The Hanford East Power House Accident

- Flash Steam-- Can it be mistaken for live steam?

- Condensate Can Climb uphill

- A common, but largely-unknown, Trap Failure Mode that led to this accident.

- Video of accident model hammering in the lab

9. Other Ways C-I-W can be Initiated in a Steam System (beside draining a line filled with condensate)

- Subcooled Water Flowing into a Steam Filled line

- infrared simulation photo's of overflowing Separtor

- Hanford U-3 Pit Accident--Cold Condensate flowing into a Steam Filled line can also cause Condensation Induced Waterhammer, and recognizing trap misplacement,

- Steam (or Flashing Condensate) entering a Water Filled line

- High pressure Condensate entering a low pressure pumped Condensate Return line

10. "Start-up" Accidents.

- This accident, which killed an operator and burned another during warm-up of a branch steam system, illustrates how less-than-carefully-considered (and enforced) shutdown and start-up procedures for high pressure steam lines can result in a fatal outcome.

Advanced Topics (Select which are applicable to your system. Three of the topics below can be covered)

11. Waterhammer in Condensate Return Systems--why it's prevalent

- Discharging HP trap discharge into pumped condensate lines.

- Discussion of Column-Closure Waterhammer when pumps activate (for Boiler Plant operators, if requested)

12. Looped Steam Systems

- What can happen if condensate gets hung up in a Looped Distribution System

- Example of "Unbalanced Manometer" type Waterhammer in loop System

- Motorola Accident

13. Flooded Manholes and Submerged Steam Piping

- The danger of Nucleate Boiling and how this type of accident can, unlike other accidents, be self-initiating. This section also compares typical trap capacity with condensate formation within steam pipes in various states of insulation and non-insulation.

- Coranado Naval Base Accident

14. Superheated Steam Systems -- Yes, they can hammer if traps are not provided upstream of isolation valves.

15 Water Slug Accelerated by Sudden Application of Steam Pressure.

- Advanced optional topic which calculates the reaction forces that can be generated by this type of non-waterhammer event.

16. Column-Closure Waterhammer

- This advanced optional topic discusses another type of water hammer which commonly occurs in steam condensate systems. It's signature is a bang when a pump activates or a trap discharges. It's generally not as powerful or dangerous as a Condensation-Induced waterhammer so it's mainly of interest to design engineers and troubleshooters. A demonstration of column separation due to evacuation is included.

17. Steam BLEVE Accidents

- A Boiling Liquid Expanding Vapor Explosion can occur when water is superheated (compared to atmospheric pressure) in a pressurized vessel that ruptures or otherwise undergoes a pressure release (such as due to a safety valve release). The BLEVE can roughly double the internal pressure in the vessel leading to total loss of containment if the vessel is weak. With sudden loss of containment, superheated water flashes to steam which creates a shock wave traveling outward from the vessel. (See Accident Investigations)

Oil Sands/ SAGD Engineers Special Topics (if requested)

1. Waterhammer Quiz is modified with questions relevant to SAGD operation and design

2. Waterhammer in the Steam Distribution Piping to the Wells at the Pad

- Based on the existing design at a SAGD Site, three waterhammer hazards are explained and then solutions recommended to design the hazzards out of the system

- Calculation of waterhammer overpressure compared with Hoop stress capacity of 6" Schedule 120 Pipe to quantify the Hazzard\

3. "Rho - V - Squared" Steam Driven Slug Flow

- Minimum Water Depth at which a Steam Line Can Slug -- below this depth, line can't slug

- Mimimum Steam Velocity to Pick Up and Acelerate a Slug -- below this steam velocity, line can't slug

- Velocity to Which a Slug can Accelerate as a f(DP) -- i.e.,the Force it can exert on a change in direction

- Dispersion Distance belong Slug Disintegrates--beyond this distance the slug won't effect pipe

4. Waterhammer in OTSG Common Blowdown Lines--the Fundamentals of why it Occurs in

Optional Wallet Card Handout "What You Need To Know"

Back

Front

My Needs for the Seminar

I need a computer projector and speakers that plug into my computer's audio output, a screen, a demonstration table (I boil water to make steam; at no time does steam pressure exceed atmospheric pressure in the can), and a white board or blackboard. Please be sure the projector and speakers are available. Before the first seminar, I will email electronic copies of the Quiz, evaluation form, and steam tables to be reproduced for each attendee and checklist. The room should be set up conference style (U-shape is good, around a conference table is even better) with attendees as close to me as possible seated at tables so they can take notes. The lights must be dimmable so the slides can be seen. Provide (or we'll make them with magic markers at the beginning of the seminar) name tags to sit on the desks (first name only) for attendees so I can call on them by name. Attendees will need pencils or pens. Attendees should be prepared to engage, this seminar is not for spectators. While I like to have fun during the seminar, I'm serious about teaching this material and giving you your money's worth. I will ask disruptive attendees to leave. It's happened twice in 15 years. Provide supervision if you need to, to insure your people are serious too. For the 9-hour seminar, suggest scheduling it for 8 a.m. to 12 noon, 1/2 hour for lunch, then return for 1 hour. The second day will end by noon.

Before the seminar, provide me information about: the steam pressures at which you distribute steam, if steam is superheated, if you return condensate, if you use inverted bucket traps, if you put high pressure condensate from Mains into a pumped condensate return, if your system is "looped", and if steam lines ever become submerged in water. The presentation is available in imperial (english) or metric units.

2nd Class Concentrating on Operators, Lahir Gold Mine, Papua New Guinea.

Feedback

Feedback from evaluations from steam operators, engineers, and supervisors, or, if you prefer, look at the verbatim comments from all attendees where "See evaluations" indicates I've scanned all evals and linked them:

- From John Hovermale whose RMF Engineers attended the Capital Steam Plant Seminar on "Understanding Waterhammer in Steam Systems 27, 28 Oct 2019", "I can speak for all the RMF’ers. They were, as I, very much enlightened on this topic. Some of these young guys could be in the position to move our company forward in the future and it’s good to get them on the right track early."

- From Chris Portelli, Process Operations, Newcrest Mining Limited - Lihir, PutPut Lihir Island New Ireland Province PNG, April 2017: Just wanted to thank you for everything you have done for us at Lihir. I had more positive feedback last night from maintenance leaders who said "The best course they had attended. Thanks again. Please send me through invoice, report, photos once you are ready and I will follow up. Once again, I thank you and also for me, it was a learning experience like I have never had before."

- From Dover & WorleyParsons Joint Engineer's Seminar Sep 19, 2012 in Calgary: "[Seminar] should be presented to all operations prior to start-up of facility"; "Videos & visualization of waterhammer are Great"; Intelligence for me is taking a complex subject and being able to explain it in simple laymen terms--well done!"; 'Excellant, Great communicator, knowledgeable"; "Excellant, the demo is wonderful"; "Very clear and concise. Great"; "Excellant presentation. Theorectical animations followed by real life examples and lab tests really hit home your points. Very intesting (sic) and captivating".

- From Veolia Energy and U. Of Penn maintenance men and operators in Philadelphia June 20 thru 24th 2012: "Very good at getting everyone to participate and made sure you understood what was being explained", "It was a great eye opener", " I would have liked the course 10 years ago", "...presentation was fantastic and i really enjoyed the class", "Wayne's knowledge about steam systems was very impressive. i learned how to check steam systems much better. This course will make me work safer."

- From Kearl Oil Sands Attendee's seminar evaluation sheets, 11&13 June 2012: "...worked with steam for 22 years...never realized how water hammer occurs". From another attendee who didn't have a power engineering ticket yet: "I can honestly say I know 1000 times more about waterhammer now", and from another attendee in answer to the question "will the seminar change the way you operate": "Yes, for sure, even though I worked in a power plant before."

- From OTSG Operator at the 10 April 2012 Cenovus Energy Seminar --"The course was awesome. It left no questions unanswered. The video demonstrations were great. Good Job."

- From Mechanical and Chemical Engineers at the Nov 2011 Vista Projects seminar: "The course gave me a completely different view of waterhammer! Great! The opposite of what I thought!", and from another engineer, "It was a really informative course for me. Speaker is a very knowledgeable person. Really enjoyed the course."

- From the 150 MW Arapahoe Power Station's Control Room south of Denver where we held their seminar, "I think this training can definitely save some accidents from happening. I know i will be looking out for situations we discussed", and from the 850 MW Comanche Power Station in Pueblo in answer to the question: "Was the seminar worth your time-- "Aw yeah".

- From U. of Chicago's Dan Carey, Manager, Central Utility Plants, "Good job. Really got the guys thinking in depth about the dangers of sub-cooled condensate in the steam system." I have attached a representative set of seminar evaluations. (See evaluations).

- From Brookhaven National Lab, 6-10 Apr 2011: "The info you provided gave me the knowledge to dispel all the myths that were taught to me over the years. Thank you."; From another Eval: "Learned i did not know as much as I thought"; From another: "One of the more useful and interesting seminars I have taken in a long time". From another: "1st time in 23 years heard the full accident report at BNL correctly, thanks". [ In 1986, two men died in a steam accident at BNL about which I wrote the article ' Surviving a Steam Accident in an Enclosed Space. This was the first opportunity I'd had to explain what happened in the accident to the site's steam fitters.

- From Princeton University, "Great Seminar" and "will make me think before I open my next steam valve".

- From Denver Xcel Energy power plant operators: "Enjoyed the class, should be a requirement for operations through [out] the corporation". From another--"I didn't think it would be [worthwhile] , but it absolutely was. I've thoroughly enjoyed both times I've seen your seminar"; and from another--"Just in case someone in the class didn't understand something, you covered it".

- CDC attendee, April 2010, "Honestly, this was the best training class i've received during my time here".

- From Imperial Oil/Esso's seminars to Operators, Engineers and ERCB representatives in Cold lake, Alberta 30,31 March and 1 April 2010,"It was the most interesting and useful course i have probably taken since I've been here...Really allowed you to ...see it with your own eyes and believe it." From another attendee--"appreciated the 'real life' examples..Excellent job teaching it..." From another--"I thought I understood [waterhammer in steam systems] before, but now i know i had it completely wrong." From another--"impossible to forget [what causes Condensation-Induced waterhammer]; it was hammered into our heads!" From another--"Every new employee should take this course before starting a steam line in Cold Lake." To see all verbatim evaluations, click this link.

- From Harvard's 9, 10 March 2010 Seminar for Mechanics and Engineers--From a steam mechanic--"Best training i ever attended" and from, I presume, the Engineering Manager--"Even though most of the seminar was a repeat for me, I still find it very useful and think it is an important topic for the entire department (engineers, operators, maintenance, & managers)". And from another attendee--"[ I ] like the phrase, 'Dig it?' ". For some Harvard attendees, this was the third time they've heard my seminar. Thanks to Craig, Kate, Susie and Bob, both Bills and John and Frank and Ralph and Joe and both Dougs, and Artie, and Octavio; but please, next year, invite some dumb guys.

- From Worley Parsons Consulting Engineers in Calgary--"an amazingly easy-to-understand seminar... Real and practical...changed my understanding of waterhammer" and from another Engineer, "I was surprised that it was so informative", and from another-- "Good pace, good level of detail, good amount of repetition, humour great", and from another "Loved the beer can demo; would have been better if you let us empty the [5 liter beer] can".

- From a Duke University steam fitter, 22 Apr 2009, in answer to the evaluation question: "Do you understand what Condensation Induced waterhammer is"--"I do now!" And from the Vice president for Facilities-- "You did a GREAT job over the last 2 days in working with our staff!"

- From an NRG San Francisco attendee, April 2009-- "I troubleshoot building steam systems and have acquired lots of experience, but your class has definitely opened my eyes on another level. Great Class!!!" From another attendee-- "One of the most informative and important training class[es] at NRG to date". From another-- "Lots of good info; a wealth of theory. The theorectical side makes it easy to understand the importance of the very few practical things you need to do to stay safe".

- From an AMEC Engineer in Calgary-- "Great learning session; the examples were very interesting. Liked the enthusiasm of the instructor and kept everyone interested". Another attendee, who i believe was a steam fitter with Imperial Oil put it more succinctly --"Did not suck".

- From an MIT steam fitter--"[The seminar] was much better than i though it would be. I thought I knew more than I did". And from Peter Cooper, the MIT Engineer who organized the seminar--"Bravo. Excellent presentation, even though we pressed you on time at the end".

- From a Provincial Government Boiler Inspector at University of Regina Seminar in answer to seminar evaluation question--What was the best part? -- to learn what water hammer really is after 30 years of thinking differently. Thanks Wayne." And from another attendee-- "Everything. This was great info from the best. ... your material [ should be] in every [steam training] course."

- From NRG steam fitter Dennis Cummings' email after 8/19/08 Pittsburgh Seminar -- "The seminar / training was excellent!...I've learned more in 4 hrs with you than days at other seminars / training."; and from an anonymous seminar evaluation asking if the seminar will change the way you operate--? "Yes, it has opened my eyes to some things i never thought of."

- From a University of Michigan steamfitter in answer to the same question above -- "for sure, it makes you really think about the steps you take during start-up and shut down"; and from a 30-year steamfitting veteran in answer to the Evaluation question "Was the Seminar worth your time"--"Yes it was, One of the best 8 hour seminar[s] I ever attended." And finally from another evaluation, a Punctuation Suggestion: "I happen to notice your use of apostrophes, particularly in the possessive neuter pronoun, was erratic"--this from one of a classroom of incredibly well educated union steam fitters at U. of Michigan who wanted to get one last correction in before leaving me in peace.

- From a steam mechanic at SubBase New London in CT after the 8/7/08 seminar: "A course like this should be mandatory for every fitter using steam within the 1st year of dealing with steam."

- And from Paul O'Neill, NAVFAC Engineer, SubBase New London , 8/12/08: "Wayne--Thanks again. I have gotten a lot of very positive feedback so far. Total of 68 trained. Some of our people had attended steam water hammer training at a large utility .... They told me that your course was more comprehensive, easier to understand and that they had come away with clear operational guidance."

- Comments from March 26,27 NASA Langley Research Center Seminar:

- The best part of the 2 days was that the knowledge was practical and useable. A lot of seminars give you theory and no practacle [sic]. This was without a doubt, the best seminar I have ever attended--a Jacobs Technology employee.

- Some Comments from February 2008 seminar for International District Energy Association:

- The visual pictures and videos really drive the point home--Univ. of Washington attendee.

- In answer to 'What was the Best Part"-- "All of it. I hope to schedule you for a visit to our University soon."

- Best Part-- "Heineken can Experiment! Excellant presentation, Thanks!"

- "Explanations were believable."--NRG Minneapolis attendee

- Models were fantastic...sad to see you didn't have time to cover [more]." -attendee from Phizer

- From Alan Murphy, Vice President & General Manager, Trigen-Boston Energy Corporation, "Wayne: I was very happy with the seminar. We are getting lots of dialog with the mechanics which is great."

- Imperial Oil attendee evaluation form, 25 Sep 07 in Cold Lake, AB-- "Presentation was awesome and material content great!...This course should be mandatory!"

- From IMV Engineer Bent Nielsen's evaluation sheet, April 20, 2007-- "This is the best seminar I've been to." From another IMV attendee-- "You're a really good teacher--make things very clear."; and from another, in answer to the Question "was this seminar worth your time?-- "Absolutely. This is a great seminar."

- From a SUNCOR attendee, Feb 2007, "You kept the audience captivated. Everything was explained in simple terms and [you] not only explained water hammer but clarified some thermodynamic principles I have not studied for a while. You're a great teacher."

- From a SUNCOR operator, "When I told my co-workers that I was going to a waterhammer course, many of them laughed at me because they all knew what it was. They proceded to take turns explaining it. They were all wrong! Thanks for the clarification."

- From Derwin Bonnie, Training Specialist at SUNCOR Oilsands, March 2007,-- "I still have people comming up to me with thanks for bringing you up here. I had an operator this morning say you were the best instructor and one of the best courses he has ever attended, he's a 17 year employee."

- From the training coordinator at another major Canadian oil company, Dec 2006-- "I got great feed back from my boss... on your seminar. Thanks I was sweating about sending a steam guy when I reviewed the text books they [were] WRONG!! [He] was very impressed and I slept real well last night."

- From Darryl Shyian at Imperial Oil, Cold Lake, Alberta, Nov 2006-- "Wayne, feedback is that the training was a success. Interesting to hear a couple of veteran operators state 'that they actually picked up a couple of points'."

- From Mike Lotito, the Engineer who organized the four Huron Campus seminars, Sep 2006, "I've had nothing but positive feedback regarding the seminars. You really got the message across. It's not easy keeping the attention of a room full of people for 4 hours, but you managed to do it."

- From a Huron Campus mid-shift worker at 3:30 a.m. in the morning-- "I have learn [-ed] more in 4 hr than 27 yrs experience."

- From a Puget Sound Naval Shipyard anonymous attendee, 8 August 2006, in answer to the evaluation question "Was the Seminar worth your time?"-- "Definite Yes."; and-- "It will change the way we design service steam systems onboard Navy Ships."

- Chuck Schuster, Steam Shop Supervisor, Brookhaven National Lab 9 Feb 2006-- "Thanks for a very informative training class. You had something for everybody and the feedback was very positive."

- From Ray Cournoyer, Engineer at Newport Naval Station, 8/17/05-- "Best part: the Lab video of the U-shaped clear tube w/ water hammer and frame by frame display. Excellent."

- From Paul O'Neill, Engineer for Subbase New London, CT, 8/17/05-- "Will definitely change the way I design."..."Info will help prevent accidents definitely; it already has, as I told you, in the incident ...where [a man was withdrawn from a manhole just before an 8" valve bonnet blew about 4 years ago. [The supervisors evacuation order was based on your [magazine] article "Condensation Induced Waterhammer".]

- From an anonymous steam worker at Newport Naval Station, 8/17/05. "THANKYOU. I used to be a pipefitter in the Utility Crew and could have used this 12 years ago. It answered many questions for me."

- Email Forwarded by Bill Lowery, Cogeneration Systems Engineer, University of North Carolina blowery@fac.unc.edu,Dec 08, 1999, Subject: Waterhammer Training

- "The best training we have ever had since I have been here at Cogen (about 10 years)" Thank you for all the effort you put into this and the concern you have for the safety of the Cogen maintenance staff, and others on campus. .. Allen

- From another UNC Steam Fitter (Read in a strong North Carolina accent)--"I been here 20 years and this is the first training session I ain't fell asleep in."

- From Vin Badali of Trigen-Phiadelphia, vbadali@trigen.com-- "Thanks again for an excellent presentation. It was truly an unusual day, as I think we all got quite a bit out of it." Regards, Vin

- From a Trigen worker -- "Worst Thing -- no donuts w/ coffee."

- From two steam fitters at US Military Academy, West Point, NY:

- "I actually learned more about condensate (cool condensate) being a cause of water hammer in steam lines, I had not realized this before."; and

- "I feel safer going into manhole[s] knowing what I learned."

- From Eric Mazzi, Manager Mechanical Services, University of British Columbia (UBC) eric.mazzi@ubc.ca --"thanks for your excellent work. The feedback from the seminar was excellent."

- From Ralph Johnstone, Chief Engineer, University of British Columbia, referring to whether or not the information presented will help prevent accidents?"--"It better or the students just weren't listening."

- From U. of Missouri Steam Operators and Fitters--

- "Theory helped me understand the example Wayne used later."

- "I now look deeper into causes [but] Skip all Math!"

- From Steam workers at Western Carolina University via Steve Flury, Director, Safety & Risk Management:

- "now that was really useful"-- attendee evaluation sheet

- "that guy understands this stuff"-- attendee evaluation sheet

- From attendees at Freescale (formerly Motorola) semiconductor manufacturing plant, Austin, Texas, June 2, 2004 from their written evaluations:

- "Best $[ dollars] spent on training ever--"

- Best Part of the Seminar: "Seeing the effects of condensate induced water hammer, i.e. lab simulations, aftermath of accidents, and the beer can imploding."

- From Washington State Seminar for State Governmental Steam Workers, June 2004:

- "GREAT job both days! Let me know when you can get the slides onto the internet so I can show it to our guys in the energy group." Jim Hayes email.

- "The best class I have ever had--" attendee evaluation sheet

- "You may have saved a life--" attendee evaluation sheet

- From Navy civilian steam worker, San Diego Naval Station, July 2004-- "Everything you talked about was explained in great detail. Need more people around like you that cares about the workers and doesn't hesitate to explain the dangers of the job."

Other Lecture Experience

- ASHRAE sponsored Distinguished Lecturer, 2001 thru 2009 lecturing to HVAC engineers in the US and Canada on water hammer in steam systems and Steam Cleaning

- Perennial Speaker at University of Wisconsin "Boiler Plant Design Course" November 1999, 2000, 2001, 2002 speaking on understanding theoretical basis for steam waterhammer.

- Georgia Institute of Technology and Georgia State University -- Calculus Instructor in Math and Business Departments

- State of Florida's Energy Office--Technical reviewer adjudging validity of energy conservation measures submitted in Technical Analysis Reports (TA's) to the to compete for grants through the Department of Energy's Schools & Hospitals Grant Program. Conducted certification training session for approximately 120 professional engineers seeking to write TA Reports in Florida in 1995 on how not to "blow it" when doing energy studies. Repeated seminar for State of Alabama Engineers.

Steam Training

All Rights Reserved | Kirsner Consulting Engineering