Chemical Engineering Magazine, August 2012.

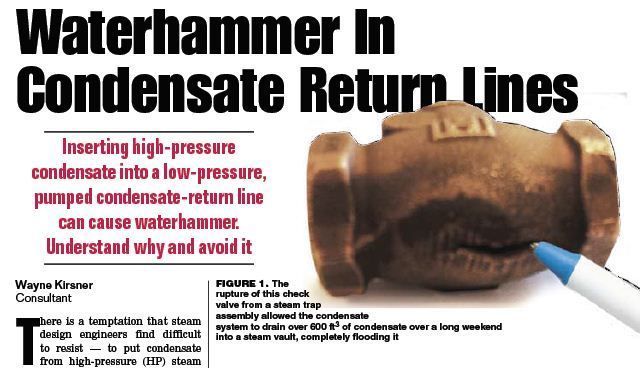

"There’s a temptation that steam design engineers find difficult to resist— putting condensate from high pressure steam mains directly into the low pressure pumped condensate return mains. After all, the condensate return (CR) main is so-o convenient--it’s generally laid right next to the outgoing steam main in the same tunnel, trench or racks as the CR main returning to the steam plant. And the good practice alternatives to dumping the condensate directly into the pumped CR, e.g., running a dedicated separate high pressure condensate return pipe back to the Plant, or, if a user’s flash tank is not near, flashing the condensate in a small vented tank at each trap then pumping it back into the CR main seem like swatting a fly with a sledge hammer". This article explains what works (and what doesn't) to avoid waterhammer in condensate return lines.